THE ERA INFLATABLE TENT

(Technical and Performance Information)

- Evolution of High-Pressure Tents

- High Pressure vs Low Pressure

- Resistance to Snow Loads

- Speed of Deployment

1) EVOLUTION of NIXUS HIGH PRESSURE TENTS

From the very beginning the NIXUS brand has brought new solutions for rapidly deployable shelters for military and rescue services around the world. In fact, since 2014, NIXUS have filed 5 key international patents related to the functionality of rapid deployment shelters and tents.

Having their own development team, prototype and manufacturing under one roof, NIXUS have both the flexibility and capability to quickly apply feedback from users to improve and develop their products. A highly skilled design and production team, state of the art software, modern production technologies and modern premises enable NIXUS to comply with the quality guidelines ISO 9001 and AQAP 2110, as well as the environmental standard ISO 14001.

Due to the materials and technologies used, NIXUS high-pressure inflatable tents are generally considered the most durable inflatable tents on the market. The patented RIBS model is the only one that uses beams formed from a bundle of 3 high-pressure tubes. Thanks to its sheer size, strength and multiple safety features, the RIBS is suitable for use as a hangar for aircraft or wheeled equipment.

Individual high-pressure tubes with a diameter of 155 mm (pressurized to 6-8 bar) serve as the supporting elements for the NIXUS tent models PRO, PRO-ISO, ERA and ECOS. These tents have a proven record in extreme climatic conditions with the military of a number of NATO countries.

For firefighting and rescue services, who prioritise light weight and compact transportation volume over durability, we have the NIXUS ERA-L model. This achieves a lower weight and deflated volume due to utilising smaller diameter of high-pressure beams (115 mm) and a lighter/thinner roof material.

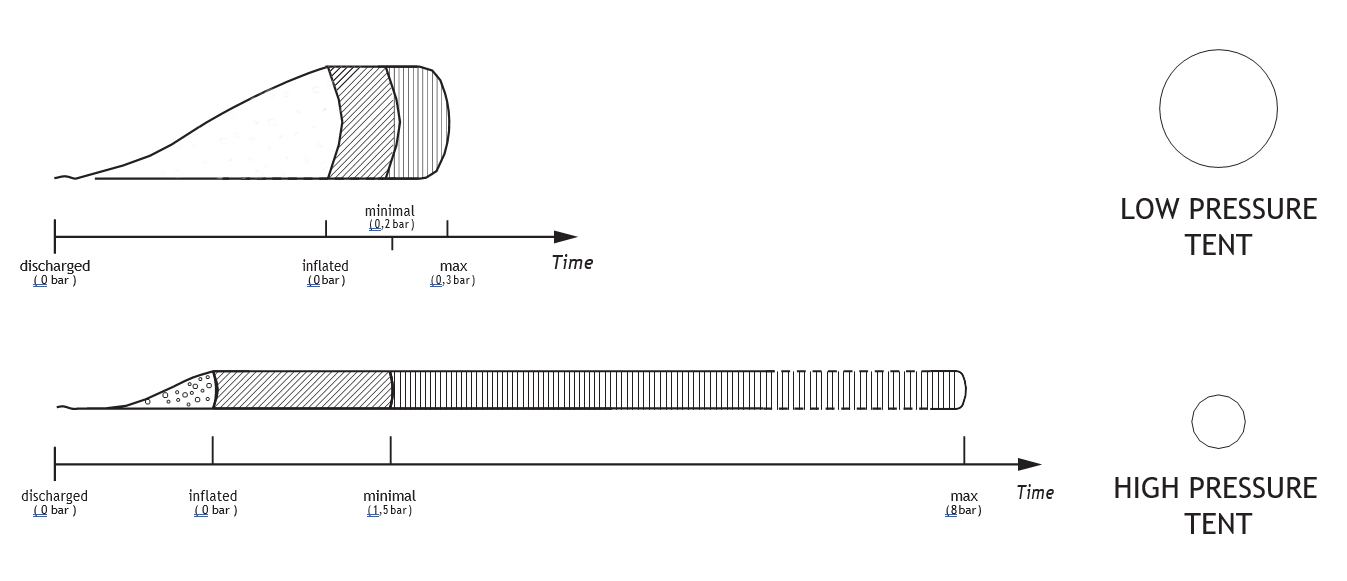

2) HIGH PRESSURE vs LOW PRESSURE TENTS

The high-pressure ERA tent structure has more than 3 times the load capacity (ERA-L has 1.5 times) compared to a traditional low-pressure tent. At the same time, ERA tents are not subject to many of the disadvantages of low-pressure tents, the worst of which is their sensitivity to temperature changes.

So what are the differences?

Low-pressure tubes are generally made by welding or gluing flat material creating a seam. This seam, as well as the material itself, has a certain limited strength which prevents the beam from being pressurized to a high pressure. On the other hand, it is necessary to generate a certain minimum internal pressure in order for the beam to function at all and the tent to stand firmly.

Typically, a low-pressure tent works in a range from 0.2 bar minimum pressure to 0.4 bar maximum pressure, at which point overpressure valves in the system are activated. This happens mainly during hot days when the air expands with increasing ambient temperature, however, the air released in this way is missing as soon as the ambient air cools down at night resulting in reduced pressure in the tubes.

For this reason, there is a need to connect low-pressure tents to an automatic inflation system which tops up the pressure whenever the temperature drops. In practice, the pressure in the tubes naturally oscillates through the entire permitted range and would naturally oscillate even more if the overpressure valves were not opened.

High-pressure tubes are directly woven as seamless tubes from significantly stronger yarns with significantly higher-pressure resistance, thanks to which the beams do not have to be so massive. Due to the smaller diameter, the minimum operating pressure at which a high-pressure tent should be erected is 1.5 bar.

However, the operating pressure of NIXUS tents is set significantly higher, but within the range of a normal compressor – which is 8 bar.

Of course, temperature fluctuations also affect high-pressure tents, but even with the most extreme fluctuations in the ambient air temperature the internal pressure does not oscillate more than 1 bar, i.e. between 7-8 bar. This is still several times the minimum required pressure to support the tent. High-pressure tents can therefore be disconnected from the compressor after inflation and will perform like a tent with a rigid/metal structure.

3) RESISTANCE to SNOW LOADS

High pressure beams, as used in the ERA, can support a much larger loads, such as from wind and snow, than low pressure tubes. For comparison, a typical low-pressure beam with a diameter of 300 mm pressurised to 0.3 bar will only carry 27% of the load of an ERA beam of 155mm diameter pressurised to 8bar. The comparison is valid for the same beam spans.

If we take the high-pressure beam ERA with a diameter of 155 mm pressurized to 8 bar as a benchmark with a load capacity of 100%, then the beam ERA-L with a diameter of 115 mm will carry 41% of the load and a low-pressure beam with a diameter of 100 mm commonly used by competing manufacturers will carry 27% of the load.

Tent load-bearing testing according to standard TOP-10-2-175

4) SPEED of DEPLOYMENT

Inflatable tents are generally easier to install than tents with a fixed structure for a simple reason – the entire tent is pre-assembled. All that needs to be done is to unroll the packed tent and start inflating. This makes installation quick and easy, even for untrained people. The disadvantage is the need for an air source – an electric pump, compressor or other compressed air source, while the speed of inflation depends entirely on the tent design and related performance.

Low-pressure pumps have a higher air output than high-pressure tent compressors, but a low-pressure tent needs 3 times the volume of air due to its larger diameter tubes, which roughly balances the time requirement. In the case of inflation from a pressure bottle, a high-pressure tent is erected faster. All the additional air that the high-pressure beams can hold goes only to increase the stability and load-bearing capacity of the tent far beyond the scope of an equivalent low-pressure tent.

As a rule, one person is enough to inflate a high-pressure ERA tent, however, more people are needed just to transport the tent to the installation site and unfold it.

Parallel inflation timeline

5) SAFETY FEATURES

Although NIXUS ERA tents operate at a significantly higher pressure than traditional tents, they are designed and tested for safe operation.

Each air circuit of the tent contains one overpressure valve calibrated to 10 bar. While the overpressure valves on a low-pressure tent work regularly on hot days, the overpressure valves on NIXUS high-pressure tents are mainly installed in case the air source selected for inflation is a high-pressure compressor with a power higher than 8 bar, or pressure cylinders with an incorrectly set pressure reducer are employed. If this situation occurs, the pressure relief valves on the beams will prevent the system from being over-pressurized.

All materials used for NIXUS high-pressure tent beams are over specified so that the beam can withstand an internal pressure of up to 30 bar, which roughly corresponds to a safety factor of 4. NIXUS tent beams have been tested by an independent laboratory and certified for pressures of up to 30 bar and components used in production are also pressure tested by the factory to ensure that production tents meet these same design criteria.

NIXUS high-pressure beams are probably the only ones on the market that meet the requirements for fire resistance thanks to the application of a non-flammable layer.

Pressure testing a tube

Testing self-extinguishing of the tube material.

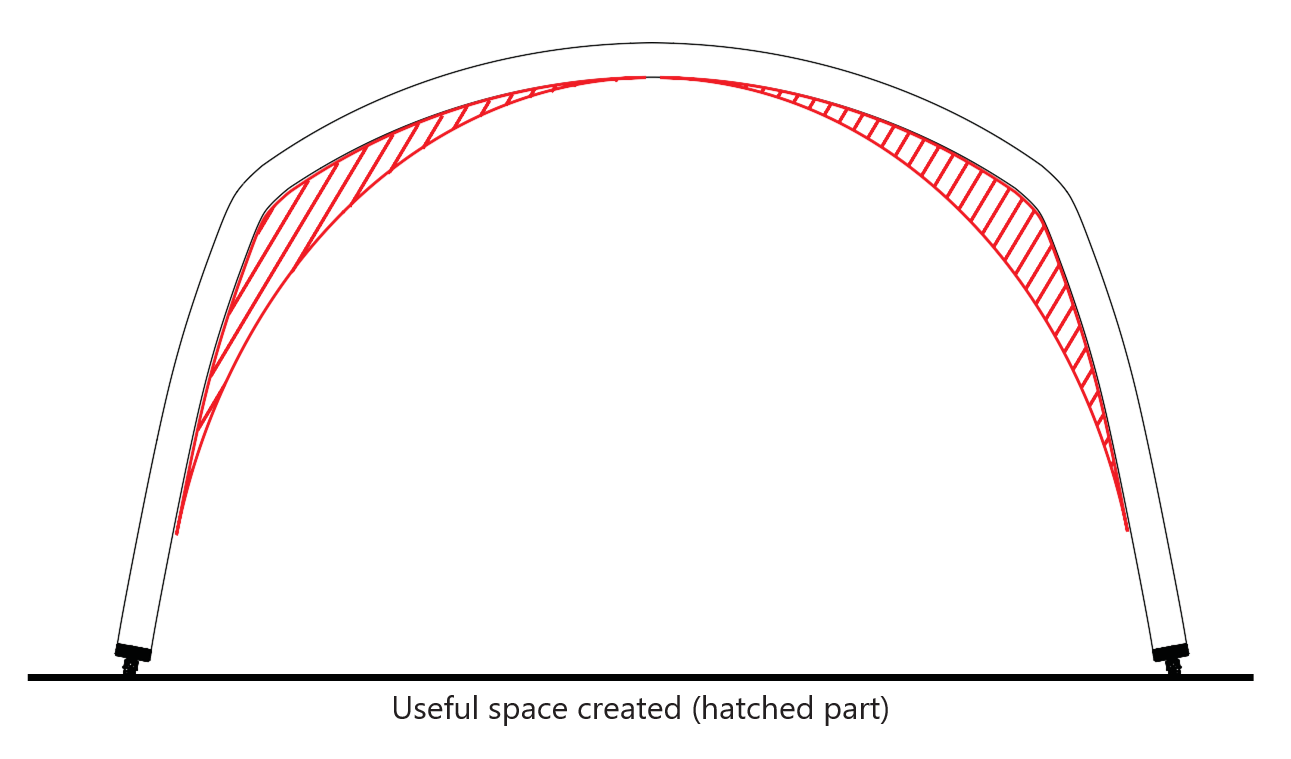

4) USEFUL INTERIOR SPACE

The high-pressure tents NIXUS ERA (Effective Roof Angle) and ERA-L are exceptional for the useful interior floor space that they offer when compared with the total footprint.

They stand out amongst all other high-pressure tents thanks to the patented shape of the bent beam which creates an extra 10 to 20% of useful space around the edges of the tent. This is achieved by making the tent sides more vertical which gives maximum head room right up to the side walls of the tent.

The NIXUS ERA high-pressure tents also have significantly thinner support beams compared to low-pressure tents, again freeing up internal space for occupants, etc.

ERA – Effective Roof Angle beams provide more space

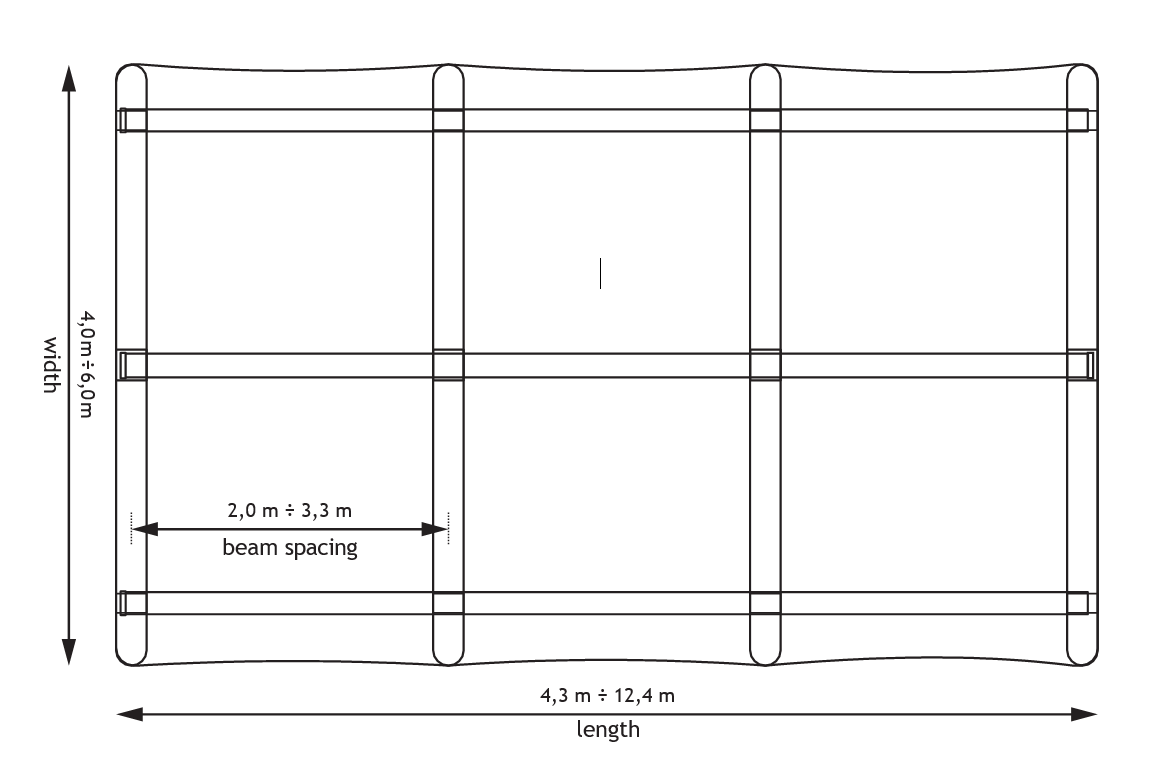

7) CONSTRUCTION OPTIONS

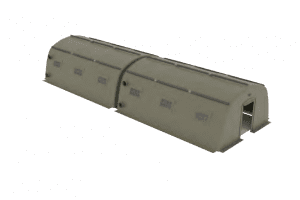

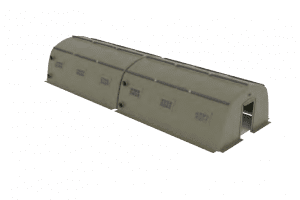

Similar to frame tents, NIXUS also offers the high-pressure NIXUS ERA with the structure on either the inside (endoskeleton) or outside (exoskeleton).

In most applications, an endoskeleton is used, but an exoskeleton is preferable for decontamination tents. With the exoskeleton, the interior space of the tent remains free of beams and is therefore easier to decontaminate at the end of an activity. Inflatable entrance vestibules can also be added, and these are designed in a similar way.

Both ERA and ERA-L tents are normally produced in widths of 4.0m, 5.0m, 5.5m and 6.0m. The length of the tent is typically between 4.3m – 12.4m, while the length of the individual module (spacing of the beams) defines the total weight and also the strength of the tents. For ERA tents, we recommend a 2.0m module for difficult climatic conditions, whereas the universal 2.5m module and the other modules at 3.0m or 3.3m are sufficient for environments without snow. ERA-L tents are available with 2.0m or 2.5m module widths.

ERA – Exoskeleton vs Endoskeleton

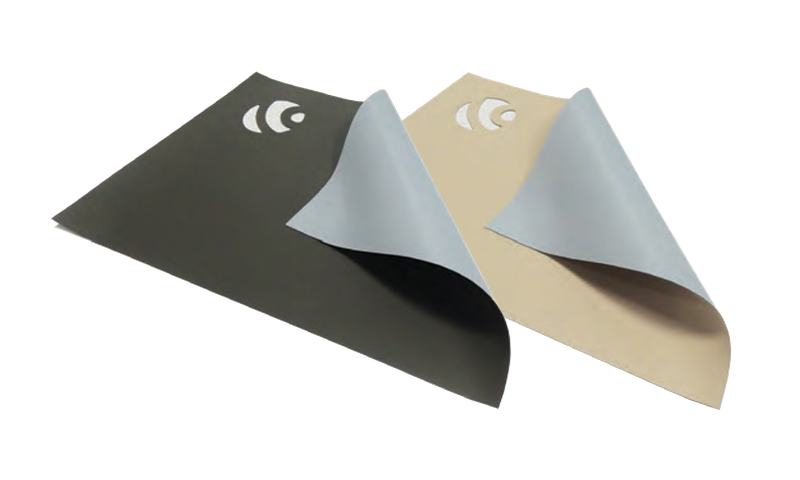

8) MATERIALS USED

ROOF

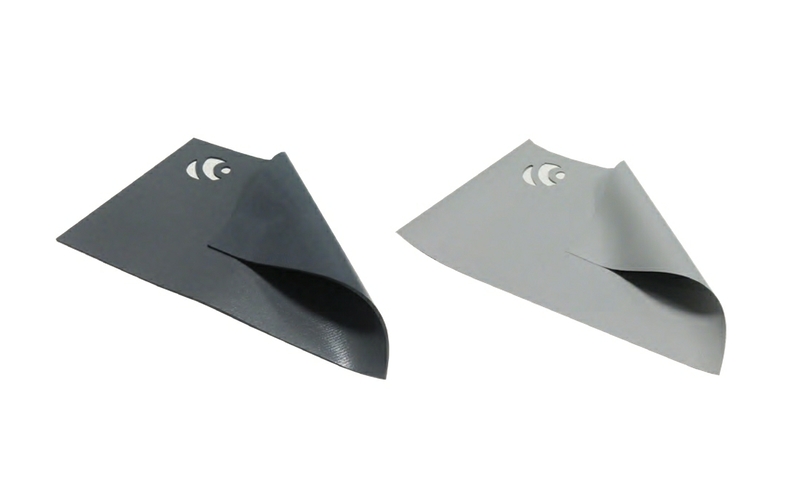

We select the tent roof material depending on the user’s requirements and considering the purpose and functionality of the tent. The roof of the ERA tent is usually made of polyester fabric 1100 Dtex, coated on both sides with a non-flammable PVC mixture with a total weight of 650 g/m2; the outside is standard matt olive green, or sand and the inside is grey. Other colours are available on request.

Two versions are available, differing in internal composition and type of PVC mixture. The standard material has a smooth surface, transmits light and withstands frost down to -40°C. The premium material has a satin surface, blocks light and withstands frost down to -50°C.

For the roof of the ERA-L tent, two options are also available – lightweight PVC fabric or light polyester fabric. The PVC fabric is 1100 Dtex polyester coated on both sides with a non-flammable PVC mixture and weighing 450g/m2. The Polyester fabric is 550 Dtex polyester coated with PU on one side and weighing 250g/m2.

The range of exterior colours for the ERA-L roof is targeted at the typical users of this model (firefighters and rapid deployment), so red, orange, grey or white are standard. However, olive green is also available for rapid deployment military units. Temperature resistance of all materials used is in the range -30°C to +70°C.

ERA – Roof Materials

INNER TENT

An internally suspended tent is available as another option for the inside of the tent. The roof, walls and floor of the inner tent are made as a single piece from high strength HT polyester 550g/m2 Dtex. To limit condensation, the material is coated on the inside with a non-flammable vapor-permeable PU coating.

The floor of the inner tent is made from solid polyester fabric 1100g/m2 Dtex, coated on both sides in a grey non-flammable PVC mixture with a total weight of 480 g/m2. The top surface of the floor is made with an anti-slip pattern.

ERA – Inner Tent

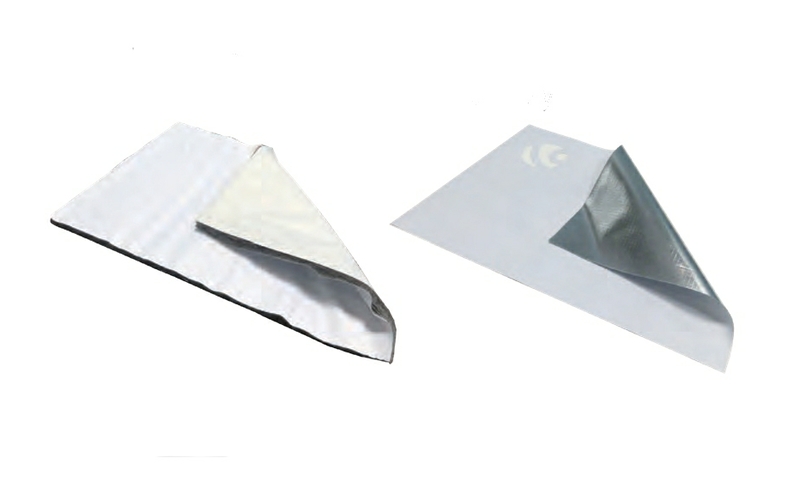

INNER LINER

The hygienic and thermal insulation liner is made from a light 70g/m2 Dtex ripstop polyester, coated on one side with a non-flammable material. It is available with a vapor-permeable PU coating where there is a need to reduce condensation and for use in humid environments.

A thermal insulation liner with a reflective aluminium coating is available for use in environments where there is intense sunlight. The thermal insulation liner is created by joining the materials together into a sandwich, where a non-combustible insulating filling is inserted between the vapor-permeable and aluminium material in a thickness according to the required insulation standard. The sandwich is held together by ultrasonic welding.

An alternative thermal insulation liner made of solid polyester, laminated on both sides, or woven with a reflective aluminium layer is also available. This liner works exclusively on the principle of thermal reflectivity.

ERA – Liner

SUNSCREEN

The outer sunscreen is compatible with the SI system and is supported on the 3 high-pressure longitudinal tubes that form the roof structure. The screen is made of a strong polyester fabric (1100g/m2 Dtex) with a low fibre density creating a mesh structure that is coated on both sides with a non-flammable PVC coating. The perforation in the mesh helps with airflow and also with cooling the surface of the tent roof. The ERA-L model can also be specified with a very light weight sunscreen made of perforated polyester fabric.

Flexible photovoltaic panels can be attached to the sunscreen and used for powering electrical equipment inside the tent, but they also assist with keeping the tent cool.

ERA – Sunscreens

9) Model ERA vs ERA-L

NIXUS ERA-L

The ERA-L is lighter version of the standard ERA. It is made with identical beam profile and spacing, but smaller diameter tubes (115 mm) to give reduced weight. This makes the ERA-L better suited to applications where the tent may have to be transported by hand. Depending on the width of the tent and the length of the modules, it has a wind resistance of up to 120 km/h and a snow load capacity of up to 30 kg/m2.

Due to its packed smaller volume and reduced weight, as well as the smaller air volume of the beams, the ERA-L is a reliable and quick-to-deploy tent for firefighters and rescue services. The total packed volume and weight of the tent, as well as the inflation speed, are almost identical to traditional inflatable tents. The main difference occurs only after setup because the ERA-L tent does not need to be continuously pressurised by an automatic pump and it can withstand more extreme weather. This leaves manpower free to focus on their real tasks instead of taking care of the tent.

NIXUS ERA

The ERA is a reliable and extremely strong tent due to its unique structure which consists of high-pressure inflatable beams with a diameter of 155 mm. These beams become rigid and incredibly strong when the tent is inflated and depending on the width of the tent and the length of the modules, can have a wind resistance of up to 120 km/h and a snow load capacity of up to 60 kg/m2.

Universal applications are possible including humnaitarian, rescue, emergency services, etc. However, the ERA is particularly popular with the military, especially with NATO countries, and is used for accommodation, command posts, field hospitals, CBRN protection and the like. The version with an external structure (exoskeleton) is ideally suited to medical and decontamination applications due to the easy of cleaning the interior as there are no strutural beams, etc. present.

10) MODULARITY

Like all other NIXUS tent models, the ERA is designed around a unified connection system so that all tents in the NIXUS range can be connected together in various ways. Here are some examples:

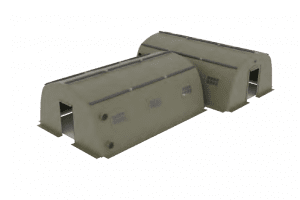

End to End

– Connecting tunnel around the doors links the tents

End to End (Full Profile)

– Connects the full profile of the tents, the internal wall is removable to form one space, if required

End to Side

– Connecting tunnel links the end door to a side door on the 2nd tent

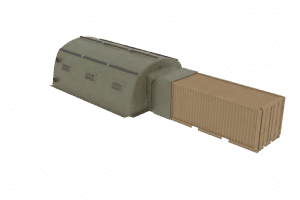

End to ISO

– Connecting tunnel links the end of the tent to an ISO container

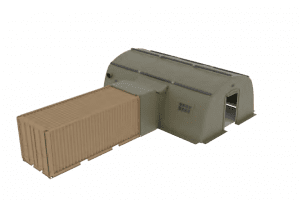

Side to ISO

– Connecting tunnel links an ISO container to the side of the tent

Side to Vehicle

– Tunnel/canopy around a side door that enables fully covered vehicle access

11) ERA SIZES

| ERA Model | Width m | Width Ft | Length m | Length Ft | Height m | Height Ft |

|---|---|---|---|---|---|---|

| NX-ERA-35-24 | 3.5 m | 11′ 6″ | 2.4 m | 7′ 11″ | 2.5 m | 8′ 2″ |

| NX-ERA-40-43 | 4.0 m | 13′ 1″ | 4.3 m | 14′ 1″ | 2.7 m | 8′ 11″ |

| NX-ERA-40-64 | 4.0 m | 13′ 1″ | 6.4 m | 22′ 12″ | 2.7 m | 8′ 11″ |

| NX-ERA-50-40 | 5.0 m | 16′ 5″ | 4.0 m | 13′ 1″ | 2.9 m | 9′ 6″ |

| NX-ERA-50-60 | 5.0 m | 16′ 5″ | 6.0 m | 19′ 8″ | 2.9 m | 9′ 6″ |

| NX-ERA-50-50-RB | 5.0 m | 16′ 5″ | 5.0 m | 16′ 5″ | 2.9 m | 9′ 6″ |

| NX-ERA-50-75-RB | 5.0 m | 16′ 5″ | 7.5 m | 24′ 7″ | 2.9 m | 9′ 6″ |

| NX-ERA-55-40 | 5.5 m | 18′ 1″ | 4.0 m | 13′ 1″ | 3.1 m | 10′ 2″ |

| NX-ERA-55-60 | 5.5 m | 18′ 1″ | 6.0 m | 19′ 8″ | 3.1 m | 10′ 2″ |

| NX-ERA-55-80 | 5.5 m | 18′ 1″ | 8.0 m | 26′ 3″ | 3.1 m | 10′ 2″ |

| NX-ERA-55-50-RB | 5.5 m | 18′ 1″ | 5.0 m | 16′ 5″ | 3.1 m | 10′ 2″ |

| NX-ERA-55-75-RB | 5.5 m | 18′ 1″ | 7.5 m | 24′ 7″ | 3.1 m | 10′ 2″ |

| NX-ERA-60-40 | 6.0 m | 19′ 8″ | 4.0 m | 13′ 1″ | 3.3 m | 10′ 9″ |

| NX-ERA-60-60 | 6.0 m | 19′ 8″ | 6.0 m | 19′ 8″ | 3.3 m | 10′ 9″ |

| NX-ERA-60-80 | 6.0 m | 19′ 8″ | 8.0 m | 26′ 3″ | 3.3 m | 10′ 9″ |

| NX-ERA-60-100 | 6.0 m | 19′ 8″ | 10.0 m | 32′ 10″ | 3.3 m | 10′ 9″ |

| NX-ERA-60-50-RB | 6.0 m | 19′ 8″ | 5.0 m | 16′ 5″ | 3.3 m | 10′ 9″ |

| NX-ERA-60-75-RB | 6.0 m | 19′ 8″ | 7.5 m | 24′ 7″ | 3.3 m | 10′ 9″ |

| NX-ERA-60-100-RB | 6.0 m | 19′ 8″ | 10.0 m | 32′ 10″ | 3.3 m | 10′ 9″ |