HUB LARGE METAL FRAME TENT

Ideal for Aircraft Hanger, Warehouse

Gym/Sports Venue, Workshop

HUB LARGE METAL FRAME TENT

Rapid Deployment Large Metal Frame Tent

Suitable for aircraft hanger, warehouse, gym/sports venue, workshop

HUB large metal frame tent is made up of two rows of standard ISO shipping containers with a NIXUS anodised aluminium structure supporting a heavy duty waterproof fabric roof. HUB frame tents are suitable for a wide variety of uses including:

- Sheltered loading bay

- Heavy goods vehicle garage

- Helicopter maintenance

- General workshop

- Covered storage area

- Military field gym, etc.

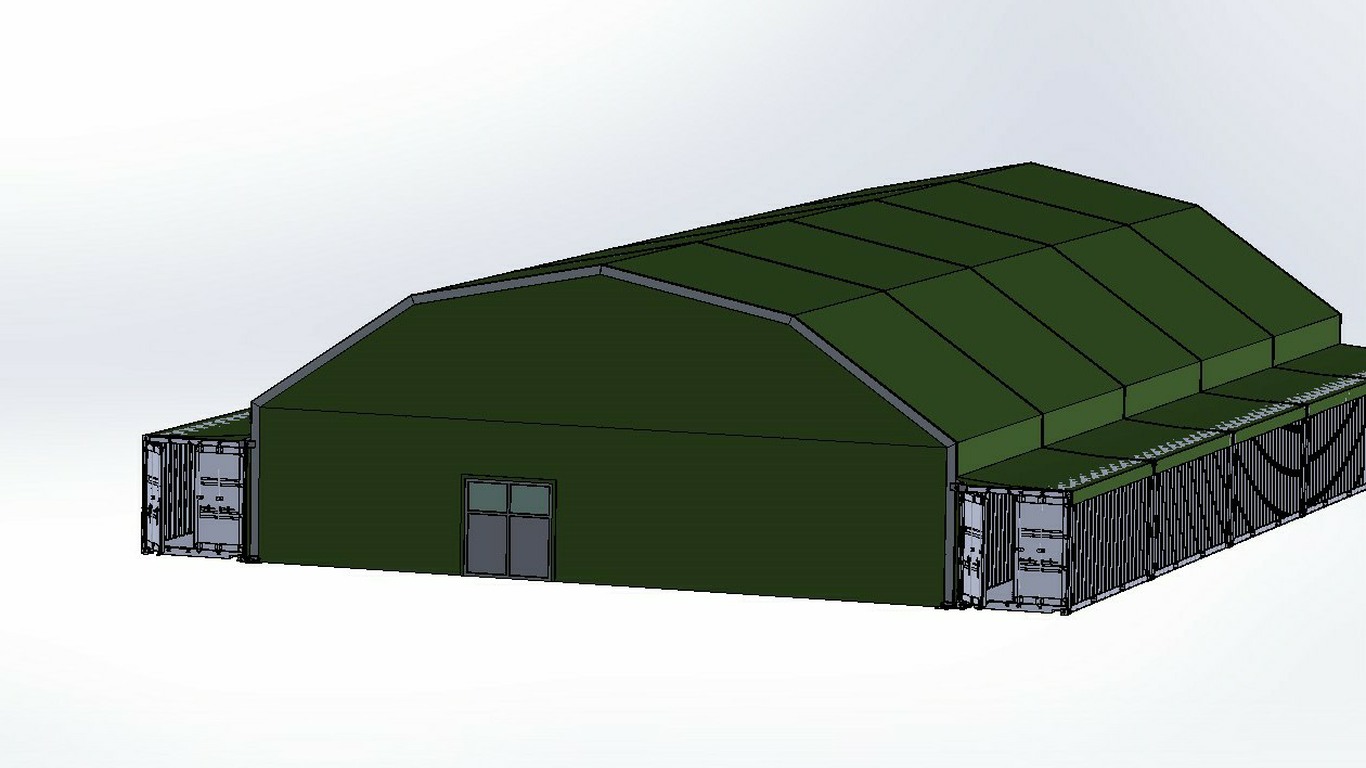

The HUB large metal frame tent can provide sheltered space up to 60 ft wide x any length, with the sides made up a combination of standard 20 or 40 foot long shipping containers. For example, we supplied and installed 3 HUBs to the British Army which were each 100 ft x 60 ft, i.e. they each comprised of 2 x 40′ plus 1 x 20′ containers on each side of the structure.

The principal advantages of the HUB is the lower cost and speed of setup when compared with erecting a traditional metal framed building.

HUB is designed to meet the need for temporary or semi-permanent structures in various applications such as hangars, storage, service, production spaces, sports venues and more. With flexibility on both size and layout a configuration to suit your exact requirements should be possible.

NIXUS HUB – APPLICATIONS

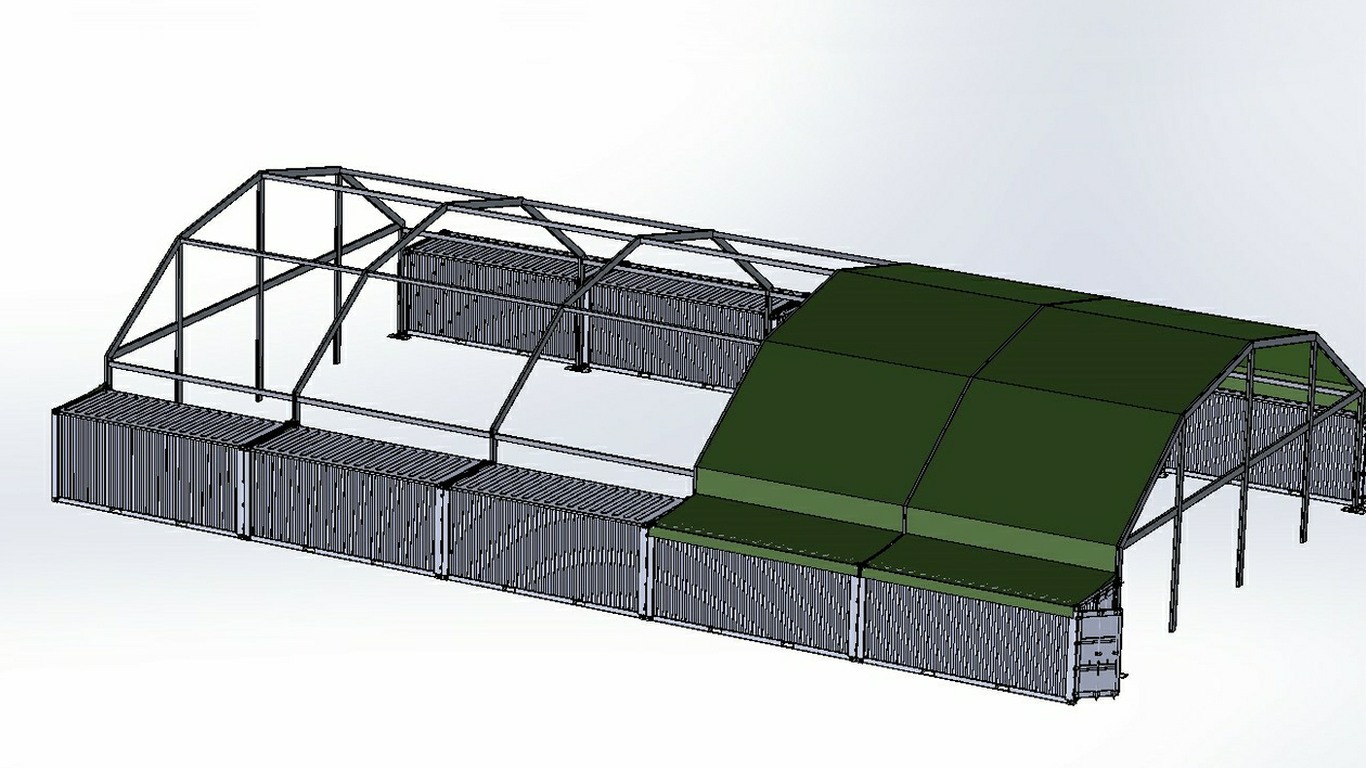

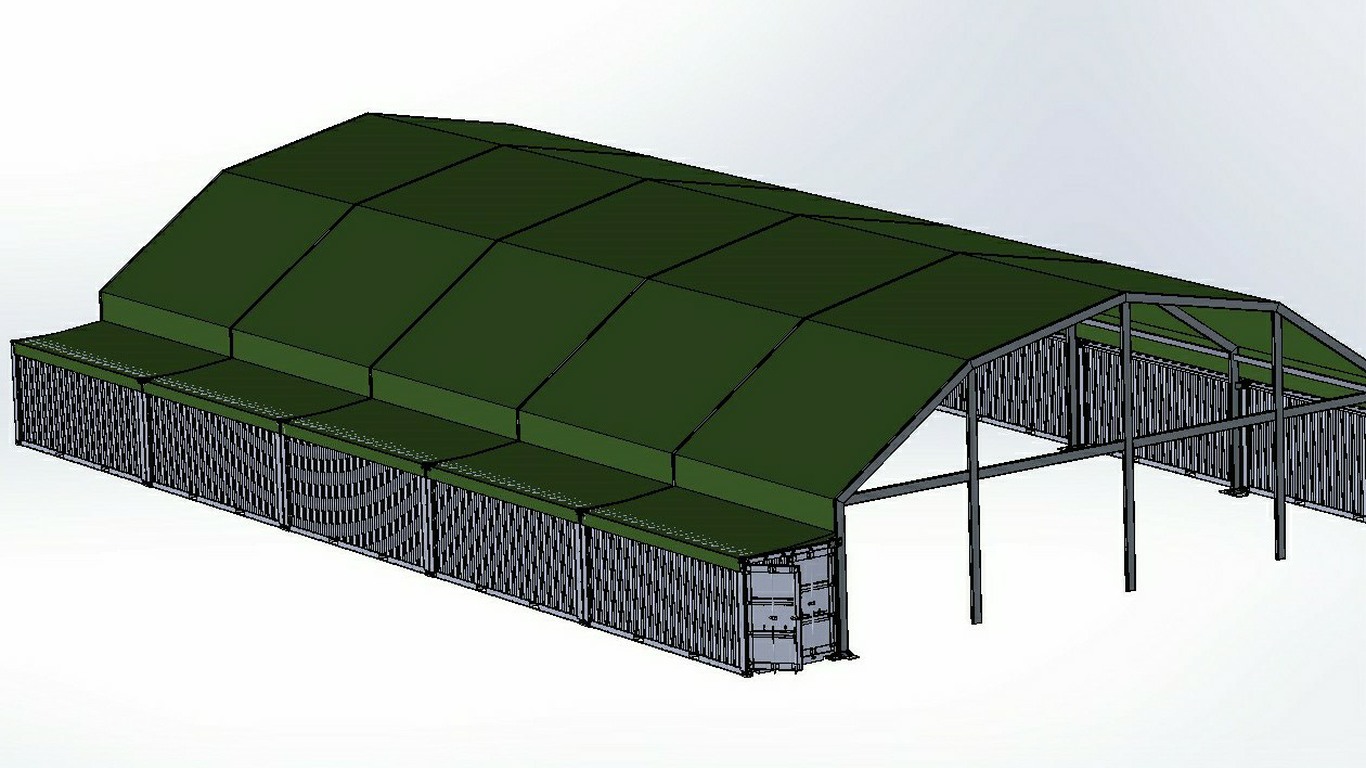

NIXUS HUB – SET-UP

Erecting a HUB large metal frame tent is very straightforward.

Firstly, anchor plates are secured to the ground with 1m long steel rods hammered into place. One plate is located at each corner where the container will be sited. The containers are then set down in two parallel rows on top of the anchor plates.

The extruded aluminium roof structure is assembled flat on the ground and then raised into position on the pivoted anchor plates. Once both gable ends and any mid main frame columns are in place, they are secured to special brackets pre-welded on to the containers.

Cable cross braces are also installed and tensioned to make the frame rigid. The purlins are then fitted in place and the fabric roof drawn over the supporting structure as well as over the containers and secured. The fabric roof is then stretched tight and the gable ends installed to make a secure and attractive building. The gable ends can contain doors and windows as well as roller shutter doors, etc.

Project Example – 100′ x 60′ Container Building Gyms for the British Army